0091P24 BURNERS ASSEMBLY LINE D90-180 P80-MF650

- Davide Bretta

- 9 nov 2024

- Tempo di lettura: 1 min

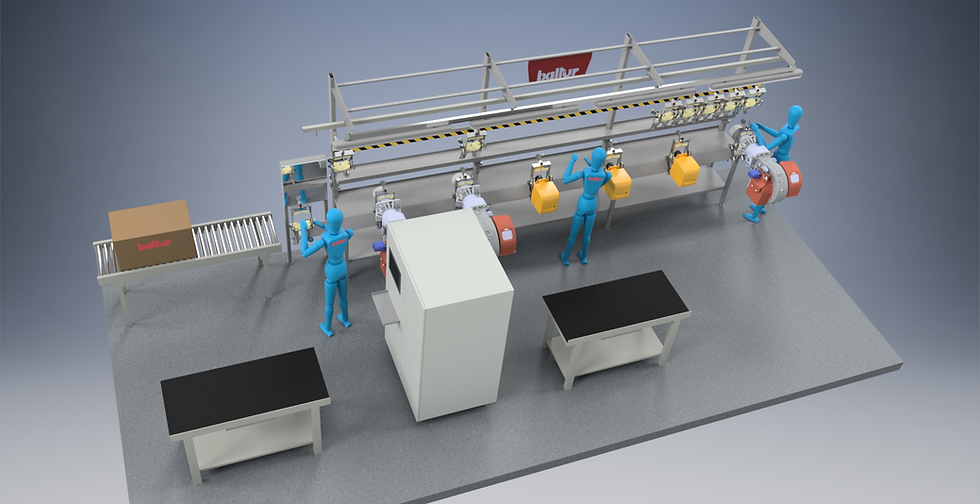

This urgently completed project concerns an assembly line for burners of various and small sizes. The line is compact, modular and includes the assembly, testing and packaging phases.

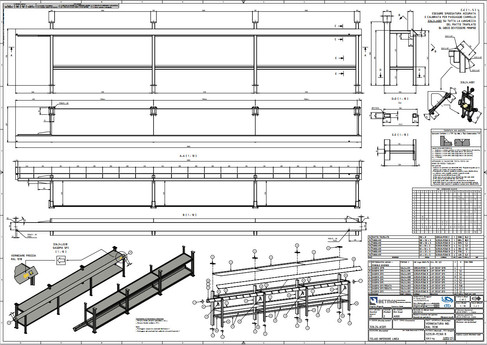

It is equipped with light trolleys that have the function of cantileveringly supporting the burners, the clamping takes place on different diameters of the final diffuser of the burners.

MINIMUM SOCKET DIAMETER | 90 mm |

MAXIMUM SOCKET DIAMETER | 180 mm |

MAXIMUM LOAD PER TROLLEY | 80 Kg |

MAXIMUM BENDING MOMENT AT THE TROLLEY | 650 Nm |

TIGHTENING / GRIP | 4 - 6 Nm |

The movement of the trolleys is manual, they are inserted with an initial and final safety block device, collected at the end of the line and return to the beginning with a simple gravity slide.

The line has been inserted into an installation layout that includes the various planned and modular phases. It is equipped with various support surfaces, lighting, control mirrors and an upper monorail for hanging screwdrivers and/or various tools.

Commenti