0236A25 CRANE ASSEMBLY SYSTEM PROJECT

- Davide Bretta

- 10 mag 2025

- Tempo di lettura: 1 min

Aggiornamento: 12 mag 2025

This was a very important project realized with a study and feasibility time of about two months and complete realization in just four months!

The project consists of designing various equipment and machines to enable the assembly and calibration of several sizes of crane booms.

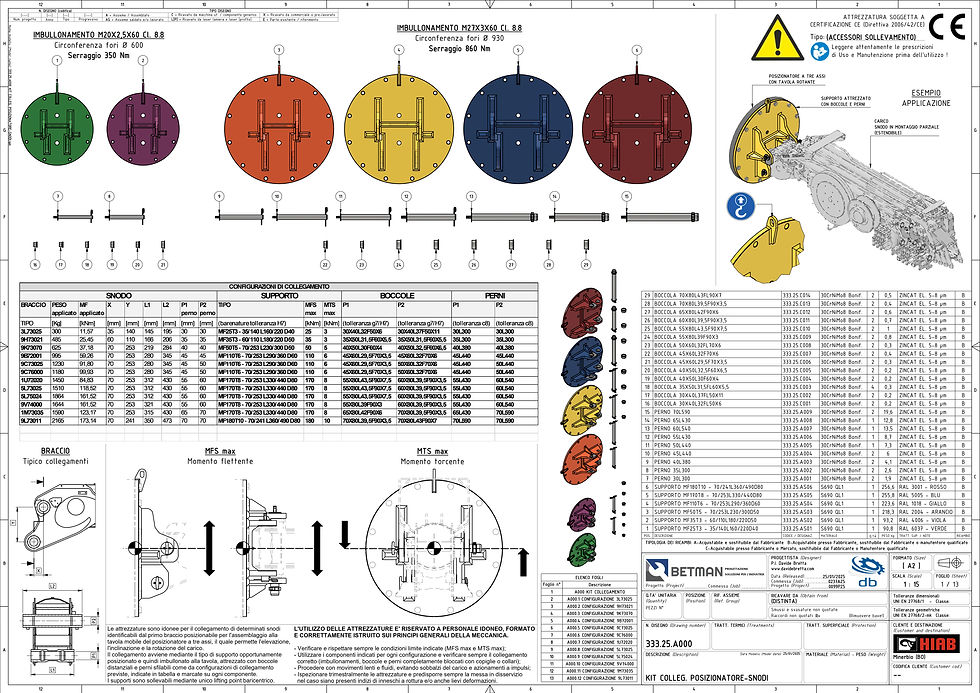

Four-axis positioning systems | Max load 10000 kg / 180 kNm / 10 kNm |

Height and inclination | Min 800 / max 1750 mm - (+/- 10°) |

Connecting rotary table | Diameter 1200 mm |

The dedicated PLC-controlled automatic positioning machine allows movement on four necessary axes:

Lifting (hydraulic 150 bar)

Inclination (150 bar)

Full rotation (gearmotor)

Crane boom extension (special pump 400 bar)

All speeds are adjustable by inverters or flow valves.

All positions can be recorded/set and recalled according to a dedicated cycle.

Adjustable transport systems | Max load 3000 kg / towable |

Support and connection systems | Configurable / Variable load by type |

N°2 formats of towable trolleys with variable height

N°12 connection configurations with only six specific calculated supports and relative pins / bushings adaptable to the crane boom.

In summary:

a complete system of machines and equipment has been created to handle, assemble and transport rather complex artefacts for this purpose.

Foto & video from testing:

Commenti